Adhesives, coatings, sealants and equipment for your manufacturing and technology applications

Explore our online shopFeatured Products

To customers in these industries

- Electronics and PCB Assembly

- Lighting and LEDs

- Electronic Displays

- Sensor Manufacture

- Wearable Technologies

- Optics and Fibre Optics

- Medical Device Assembly

- Orthopaedic Implants

- Aerospace, Defence, Firearms and Ordnance

- Battery and Fuel Cell Manufacture

- Automotive, Transportation and Marine

- Electric Vehicle Manufacture

- Instrumentation and Machinery Manufacture

- Materials, Chemicals and Composites

- Education and Consultancy

What makes a good adhesives supplier?

Every adhesives application is unique, complex and challenging. Choosing and evaluating an adhesive involves considering every aspect of the application, from design to production to processing, in line with the business’ priorities, like performance, productivity or process improvement. Because of this, manufacturers commonly look to adhesives specialists to support them with product selection and integration. This relationship works best as a long-term partnership that covers both current and future processes, rather than one based on the transactional supply of materials

To help companies pinpoint what to look for in an adhesives partner, we’ve written up the results of a roundtable discussing the question, What makes a good adhesives partner?

Featured Case Studies

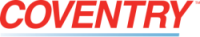

-

Bonding and sealing polyethylene tanks using MMA adhesive

A rotational moulding company producing LDPE tanks needed an effective way to repair blow holes in their polyethylene products. After consulting IPS Adhesives, they trialled SCIGRIP SG400LSE, a specialised adhesive for low surface energy plastics. Its successful application reduced waste, enhanced product quality, and achieved significant cost savings.

Download the Case Study

0.28MB Download -

Dispensing for particle sampling

Apacor Ltd, a leader in in vitro medical diagnostics, required a way of scaling up their recently launched air sampling product. By integrating a preeflow eco-PEN and a Fisnar F4303N ADVANCE robot into their workflow, they achieved precise and repeatable droplet dispensing onto their glass substrate.

Download the Case Study

0.18MB Download -

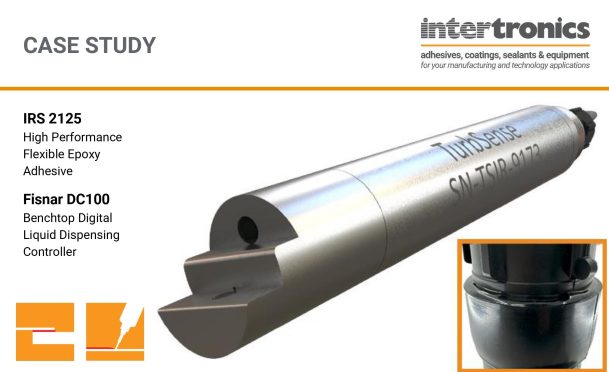

Flexible adhesive improves technical performance

Process Instruments, a UK-based company specialising in water analyser instruments, required a material which could secure their PG13 threads and create waterproof seals in their sensors. IRS 2125 flexible epoxy adhesive was selected due to its strong bond strength, water resistance and straightforward application from convenient cartridges.

Download the Case Study

0.19MB Download -

Reducing maintenance costs in automotive manufacturing

A leading German automotive manufacturer faced challenges dispensing a highly abrasive material using traditional piston pumps, leading to frequent and expensive valve replacements. Transitioning to a preeflow eco-Pen 600 volumetric dispenser enabled the manufacturer to meet dispensing throughput targets and substantially cut down on maintenance expenses.

Download the Case Study

0.16MB Download -

Potting compound and accurate, reliable dispensing for automotive lighting

Requiring a potting compound which could provide environmental protection to their high-powered outdoor LED lights, lighting manufacturer Venta Global selected IRS 3078 and a metering, mixing, and dispensing system to create a straightforward and repeatable process.

Download the Case Study

0.29MB Download